Over the last two weeks, we’ve watched in horror as the citizens of Ukraine have been subjected to violence, terror, and displacement. This war is a humanitarian tragedy and its fallout is far reaching. As someone who has built her career in macroeconomics and global supply chain, I want to call attention to a new front in global conflict.

For decades we’ve poured trillions of dollars into strengthening the infrastructure of other nations without realizing the consequences. Economic warfare is the new arms race. Globalization has distributed and transformed our supply chains into a mass of complex and interdependent processes.

Leveraging global comparative advantages has been exceptionally productive, deflationary and beneficial to consumers and companies over the last two or three decades; however, we’ve also created our own Achilles’ heel — deep dependencies on other countries’ sourcing of raw materials, manufacturing and industrial know-how for the supply of goods critical to our social and economic well-being.

How concerned should we be?

While European dependence on Russian fossil fuels has dominated headlines recently, it is only one example of a key driver crippling NATO’s ability to take a stronger economic stance against Russian aggression.

The picture in the U.S. is equally concerning. Domestic access to key agricultural, industrial and pharmaceutical inputs, as well as to the computers and machines underlying our physical and economic well-being are highly concentrated in one or two other countries, with little or no viable alternatives.

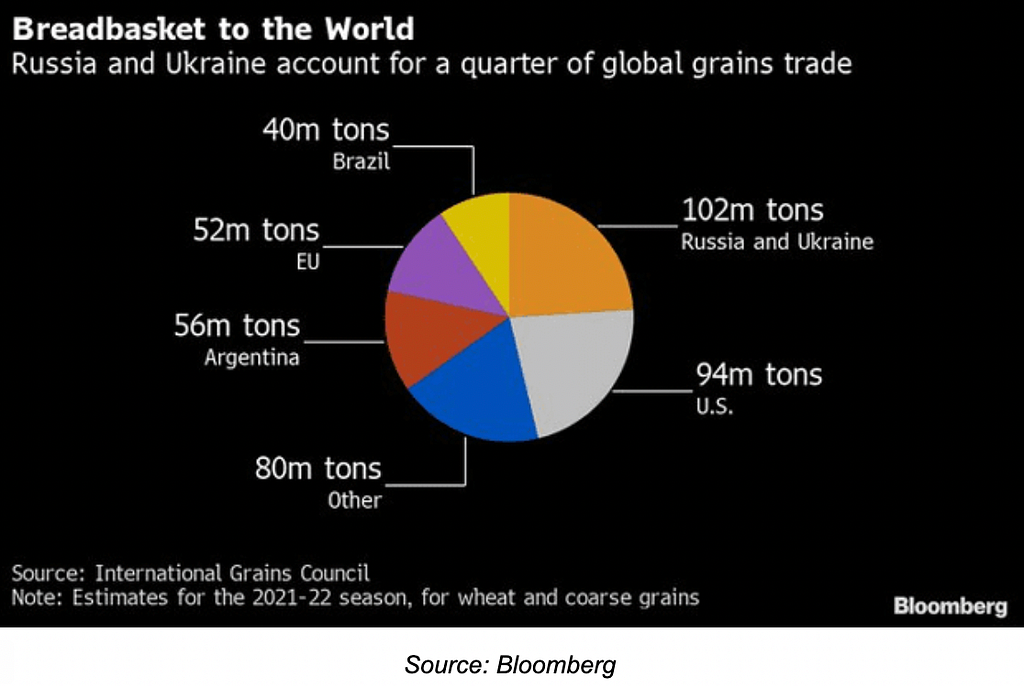

For example, Russia and Ukraine make up over one quarter of the world’s grain trade. Russia, Belarus and China comprise over 50% of global potash (a key fertilizer ingredient) production. Russian natural gas is used not only for European power but also to produce the ammonia used as a key ingredient in the majority of European and U.S. nitrogen fertilizers.

Our supply chain concentration risks are not limited to agriculture and energy. Other critical goods are also perilously sole-sourced. The global economy depends on Taiwanese firms for 92% of leading-edge semiconductor production,¹² and China was estimated to control 55% of global rare earths mining capacity in 2020 and 85% of rare earths refining. Rare earths metals are essential to manufacturing everything from engines to airplanes to defense equipment. ³

Even if we are able to diversify our materials sourcing, we’ve severely depleted our manufacturing capacity. Manufacturing’s share of gross domestic product in the U.S. has shrunk from 27% to 12% over the last several decades, and with it, our expertise and manufacturing innovation and edge. Decades of focusing on labor as a cost to be controlled — not an asset to be invested in — have depressed wages and decreased the manufacturing workforce by 7.1 million jobs, while also contributing to companies’ challenges finding and keeping skilled talent.⁴

What should we do?

As one of the most innovative and entrepreneurial countries in the world, we are far from helpless. But the time to act is now.

There are clear regulatory and fiscal measures we can take to shore up key inventories, better educate our workforce, and drive government investment in reshoring heavy capex industries like semiconductor fabrication. We also need to invent completely new solutions to innovate our way to supply chain resilience.

Here are five technologies we’re focused on as a firm at Eclipse in pursuit of supply chain resilience and innovation. We see these technologies as mitigating not only the threats posed by trade disputes and economic warfare, but also the ongoing risks presented by a worsening climate, future global pandemics and other catastrophes as well.

1) Energy Storage and Materials.

China controls over 75% of global cell fabrication capacity for advanced batteries, as noted in the Department of Energy’s report. Most batteries in use today have chemistries that typically store power for four hours or less. To take full advantage of alternative, renewable energy sources like wind and solar, we need batteries with 12- to 16-hour duration. We also need to reduce, where possible, our dependence on our current sources for rare earth minerals.

We’d love to see smart innovations in battery duration and sustainable battery chemistry, like Enovix, Malta.inc, and ESS, and other rare earth mineral supply chain innovations like LiLac and KoBold Metals.

2) Smart Grids and Transmission.

States are vulnerable to climate catastrophes and energy supply volatility due to the limitations of today’s regional grids. For example, the Northern states have limited access to the abundant solar power generated in the South, and coastal states can’t easily access wind power from the Plains.

In the absence of a macro grid, we’d like to see more technologies like Sparkmeter that take a more intelligent approach to the electricity we already produce through the use of smart grids. These demand/supply-responsive technologies enable individuals and businesses to use what they need and then sell on any excess capacity through a combination of their solar panels and EV battery storage.

3) Vertical Farming

Highly-concentrated crop geographies, commodity access, pricing volatility and climate catastrophes place our sources of key grains and other crops at risk. Additionally, soil management practices that release nitrous oxides (N2O) into the atmosphere are the largest single source of agricultural greenhouse gas (GHG) emissions at 49%.

Several promising technologies, like Iron Ox, Gotham Greens, and Bowery Farming offer the possibility of mitigating these risks by leveraging aeroponics and hydroponics.These alternatives to traditional cultivation can result in dramatic reductions in the utilization of resources, for example, an estimated 95% less water usage.

4) Closing the Industrial Workforce Skills-Gap.

The U.S. has millions of open positions in skilled industrial labor — over 2.4 million job vacancies will need to be filled in manufacturing alone in the next five to six years. However, high turnover and churn are only widening the divide between the supply of and demand for skilled workers. The impact of the COVID-19 pandemic highlighted labor shortages and skills gaps in our trucking, manufacturing and warehousing operational and technical workforce.

To increase workforce participation and broaden technical skill sets, we’re paying attention to companies focused on providing upskilling and advanced tools and training for the U.S. workforce, such as Guild Education. We appreciate the upskilling and education initiatives kicked off by major warehousing and logistics employer, Amazon. There is a lot more work to be done here and a huge gap to close.

5) Advanced Manufacturing.

To build a full-fledged solution to meet at least critical supply levels of electronics and specialized equipment, we can’t simply rely on reshoring semiconductor manufacturing. Electronics manufacturing is a multi-step process involving not only wafer fabrication and etching, but also full electronic PCB assembly, final assembly, packaging and software installation.

To compete in a globally competitive manufacturing environment, the solution to reinvigorating our onshore capabilities can’t duplicate current overseas processes. We lack the component supply chains, competitive labor rates, downstream manufacturing facilities, and these days, key knowledge.

Instead of copying others, we have a significant opportunity for innovation to drive entirely new solutions for a U.S. manufacturing base. We are world leaders in cloud computing, advanced robotics, AI, data science and IoT controls. We need to see further innovation in applying these technologies to manufacturing, and in supporting the transformative efforts of companies like Vulcan Forms, Bright Machines, BrightInsight, and Instrumental in rethinking and reshoring critical manufacturing capabilities with cutting-edge productivity and precision.

We need to act now.

Wars, global pandemics, climate disaster, trade disputes and financial instability are fast becoming the norm and there’s no sign of the worldwide chaos ending any time soon. We can’t keep lurching from reacting to one crisis to the next, patching up, but never rethinking the physical and digital status quo as we go. It’s time to rethink, invest and rebuild supply chains based around the concepts of resilience and agility, so we can be proactive in our approach to the next challenges.

Follow Eclipse Ventures on LinkedIn and Twitter for the latest on the Industrial Evolution.

Sources:

¹ https://www.reuters.com/business/global-food-supply-risk-russian-invasion-ukraine-yara-says-2022-03-01/

² https://www.fpri.org/article/2021/06/us-jobs-rely-on-taiwans-security/

³ https://www.whitehouse.gov/wp-content/uploads/2021/06/100-day-supply-chain-review-report.pdf

⁴ https://www.whitehouse.gov/wp-content/uploads/2021/06/100-day-supply-chain-review-report.pdf