Electric cars may dominate headlines, but boats move 80% of the world's goods. Arc is on a mission to transform marine transport, a $432 billion cornerstone of the U.S. economy that has seen little innovation. To build better boats, they must be electric.

Electric boats are inherently superior: they offer lower maintenance, higher efficiency, zero emissions, instant torque, reduced operational costs, and quieter operation. Yet, they've faced a critical barrier — they’ve had insufficient battery capacity to rival gas-powered boats.

This battery capacity issue has major long-term implications for sustainability. The marine industry today accounts for 3% of global greenhouse gas emissions, comparable to industrial nations like Russia (3.4%) and Japan (4.6%). The International Maritime Organization aims for net-zero emissions by 2050, and ports are already imposing emission limits. Without action, some shipowners may soon find themselves unable to operate in many ports.

In 2021, lifelong boater Mitch Lee teamed up with his former college classmate Ryan Cook. Recognizing this potential, they knew replacing gas-guzzling boats was a no-brainer — the challenge was in the execution.

Everyone agrees electric boats need to exist. The idea is obvious, but what’s not as obvious is how. This is a rare opportunity where we control our own success through our execution.

Arc, founded by rocket engineers, EV experts, and passionate boaters, aims to revolutionize marine transportation. They’re not just creating electric boats, they’re crafting the highest-performing vessels on the market. Rather than retrofitting gas boats, Arc designs boats around their batteries from the ground up, unlocking the battery capacity needed to transform the future of boating.

Electrifying Everything on the Water

Fortunately, “the electrification of transportation is a foregone conclusion,” says Greg Reichow, a former VP of Production at Tesla and Eclipse Partner, who led the company’s Series A in 2022.

Arc and its team of experts from SpaceX, Rivian, Tesla, Brunswick and MarineMax, are leveraging the groundwork laid by the automotive industry by utilizing EV infrastructure, battery and propulsion systems, and supply chains. The talent, skills, and infrastructure from the auto industry, coupled with maritime domain expertise, provides Arc with the foundation and resources to innovate rapidly and efficiently.

Arc is starting with the $31 billion consumer boat market, then working its way up to larger ships until everything that floats is electric. This strategy mirrors Tesla's early approach with the Roadster, which was the first battery electric sports car to utilize lithium-ion battery cells. Tesla captured revenue from a niche market of car enthusiasts and reinvested revenue to develop more advanced and affordable models like the Model S and Model 3, driving innovation and reducing costs.

Similarly, Arc plans to build expertise and scale its technology, poised to revolutionize the marine industry just as Tesla transformed the automotive world.

Riding the Wave of Fast Learning Cycles

Arc has smashed product-launch expectations, introducing the Arc One and Arc Sport — two consumer electric boats — from 0 to 1 in just 3 years. These fully electric, zero-emissions boats are priced competitively with combustion-engine counterparts. And they did it using a fraction of the capital that most EV companies have used to bring a first product to market.

By using off-the-shelf components like automotive grade battery management systems and charging infrastructure, Arc reduced the “activation energy” needed to launch an EV. However, building a boat presents unique and difficult engineering challenges in its own right. The team needed to achieve boating breakthroughs across three pivotal dimensions:

- Power. Navigating water demands more power than land-based travel. Boats require higher continuous power motors than what you’d find in a typical consumer EV.

- Energy. Wake sport boats have gas tanks nearly triple the size of sedans. That’s why Arc uses a battery pack three times the size of a model Y.

- Weight. The Arc One's battery weighs 2,800 lbs, which is a challenge for boat owners who need to trailer their boats and have weight limitations. Designing strong lightweight hulls to offset the battery weight is needed to provide a comparable customer experience to gas.

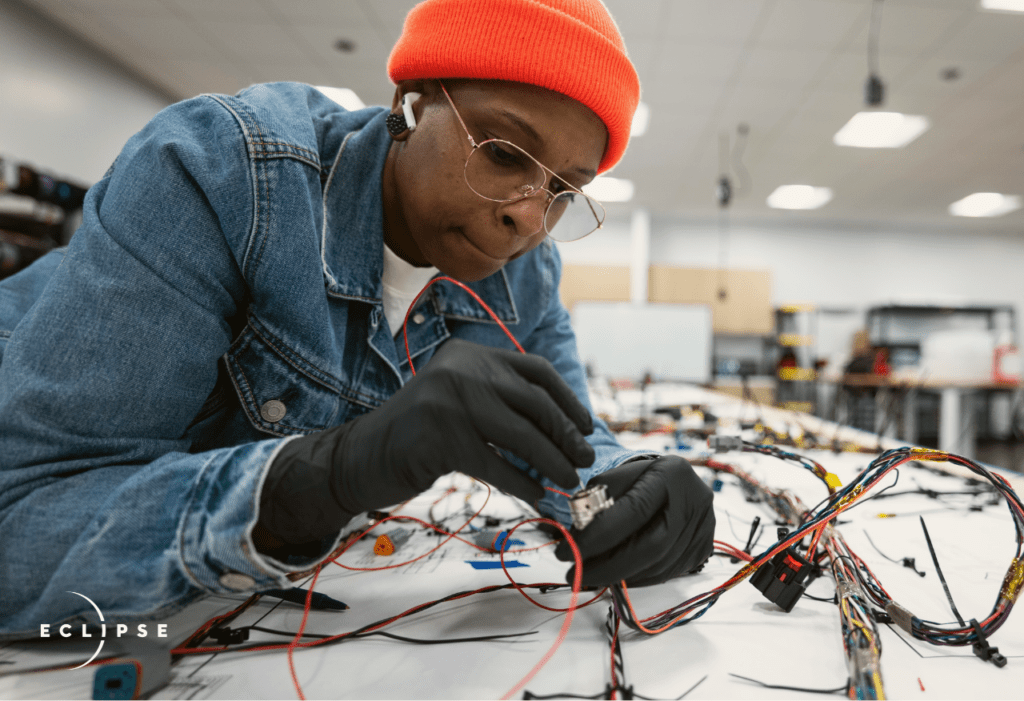

Guided by EV veterans like Reichow, Arc decided which components to make in-house and which to source off-the-shelf for optimal efficiency. They found off-the-shelf batteries weren’t going to get the job done, for example, so they designed custom batteries for better performance and weight distribution.

When forging something groundbreaking, it often means manufacturing key components yourself. While building these components yourself can be challenging, there are also significant advantages. Because it forces you to have a deeper understanding of the fundamentals, it enables faster cycles of learning, and when done correctly, results in a superior product.

Arc’s Torrance, California factory is a 150,000 sq ft hub, where engineers, supply chain managers, designers, and manufacturers work together to overcome the challenges that come along with transforming an industry. Arc’s approach allows for faster learning cycles and lower capital requirements compared to traditional boat manufacturing.

“Assume your first attempt won't work, nor your second. Maybe by the third or fourth iteration, you'll start getting it right,” Cook says. “This applies to everything from the powertrain to the hull. Expect to go through several iterations before delivering to a customer. The key is speed — quickly move past the imperfect first versions to learn and improve faster than if you waited.”

Ask any one of Arc’s team members how they stay the course through such rapid progress and inevitable setbacks, and the conversation always comes back to Lee and Cook’s mantra: relentless execution. Each member of the 100-person team is a “pragmatic owner” — from Smit Goswami, Head of Supply Chain, who prides himself on forging deep, meaningful relationships and brings experience in supplier management from SpaceX, to Aaron Levine, the Software Lead who formerly led iOS infrastructure at Snap and now pursues the novel challenge of testing software on the water. “Everyone here has a tremendous amount of responsibility, and that makes them feel very empowered,” Cook says.

Everyone here has a tremendous amount of responsibility, and that makes them feel very empowered.

The Future of EV Transportation

Looking over the horizon, emissions must be drastically reduced by 2050 to avert a climate crisis. Physical industries, including agriculture and transportation, constitute 75% of the global economy and emissions. The outdated infrastructure can no longer support sustainable growth.

At Eclipse, we believe Arc’s innovations — spanning battery design, firmware, and infotainment — could, one day, help accelerate transformation of other sectors. Picture electric agricultural equipment reducing environmental impact and increasing efficiency, or construction sites with electric machinery minimizing noise and air pollution. Just as EV auto technology accelerated the electrification of the marine industry, we believe EV boat technology can one day help transform broader transportation, driving us toward a more innovative and sustainable future.

For now, Arc’s purpose-built boats are unlocking the power needed to evolve the future of boating, bringing us one step closer to a more sustainable future.

Follow Eclipse on LinkedIn or sign up for Eclipse’s Newsletter for the latest on the Industrial Evolution.

Related Articles

How Mytra is Transforming the Lifeblood of Our Physical Economy: the Supply Chain

Read More

Advancing the Future of Aerospace and Defense in the U.S.: Inside Ursa Major’s Flexible and Scalable Manufacturing Innovation

Read More

The Next Frontier of Clean Energy Storage: Our Investment in Peak Energy

Read More